We have various types of laser manufacturing equipment and multi-field process technology experts, to achieve the whole process of medical device production control by using mature project development process and quality control system, accumulate traceable database from prototype manufacturing to commercial mass production, so as to reduce product risk and ensure the safety and effectiveness of medical devices.

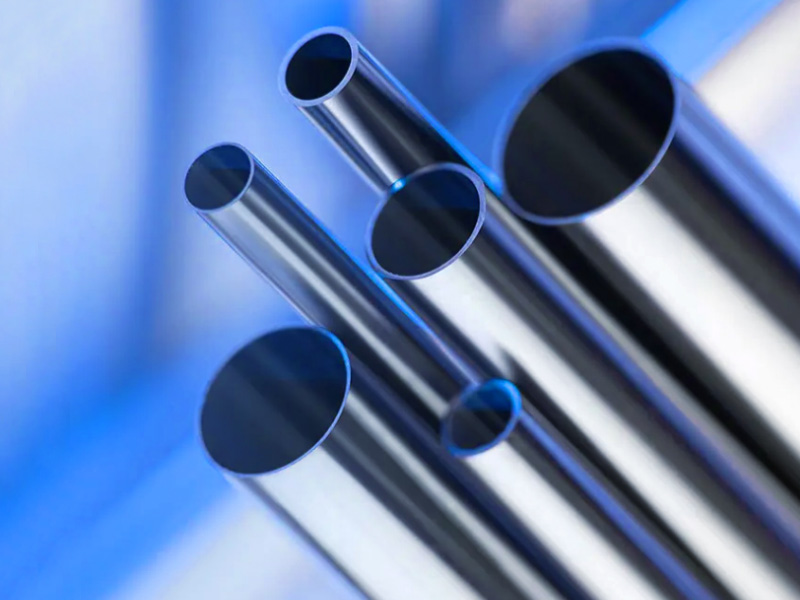

With strong supply chain management capabilities for raw materials, you can choose the most reasonable and appropriate raw materials for different product applications which meet or exceed your expectations.

We continuously upgrade processing and testing equipment, and have established a full-process technology database to produce your product with high quality and efficiency.

Our comprehensive project management process guarantees exceptional outcomes for every project we undertake.

We have established a highly advanced production line for Nitinol components, supporting both Class II and Class III medical devices.

Exceptional laser manufacturing capabilities:

Advanced nitinol processing capabilities:

Industry leading metal fabrication capabilities:

Simulation and testing laboratory

Product assembly capabilities

Class 10,000 cleanroom

Supply chain support

Parts cleaning and rinsing

Quality support and process verification

Product assembly capabilities

Class 10,000 cleanroom

Supply chain support

Parts cleaning and rinsing

Quality support and process verification

ISO 13485 quality management system certification

Advanced product quality planning (APQP)

Installation qualification(IQ), operational qualification(OQ),and performance qualification(PQ)

Production part approval process(PPAP)

Process failure mode and effects analysis (PFMEA)

Measurement system analysis (MSA)

Process capability analysis(Cp、Cpk)

We take pride in our customer service and aim to provide 5-star support.

+86 19005195075