Our professional and efficient prototyping team will work closely with you to understand your demands. Whether you provide 2D drawings or complex 3D engineering models, we will support you throughout the development process. We engage in product manufacturing from the incubation stage, using simulation analysis, process databases and performance testing centers to deliver effective prototyping solutions and provide customized, specialized manufacturing services.

Our experts from materials, mechanics, optics and other fields will help you optimize the product design for manufacture & assembly (DFMA) at the initial phase, including product structural design analysis , raw material selection and manufacturing process feasibility analysis and more.

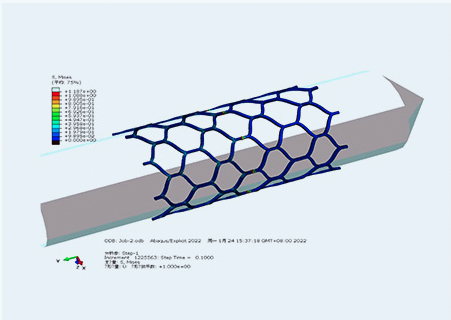

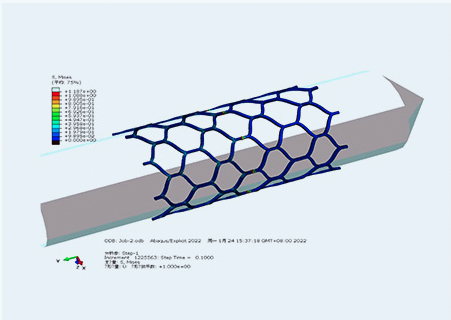

01We will collaborate closely with you to optimize structural design toensure the manufacturing feasibility and safety by simulating mechanical properties such as radial force, compressibility, and fatigue performance. Our process shortens the development cycle and accelerates your time to market.

02

We ensure the rapid completion of prototype manufacturing with experienced process team, various advanced manufacturing equipment, stable supply chain resources and perfect production management system.

03Our testing laboratory has a wide range of testing instruments to verify prototype performance which can help you identify design defects or safety issues to optimize the structural design of products and reach performance requirements.

04

Our experts from materials, mechanics, optics and other fields will help you optimize the product design for manufacture & assembly (DFMA) at the initial phase, including product structural design analysis , raw material selection and manufacturing process feasibility analysis and more.

01

We will collaborate closely with you to optimize structural design toensure the manufacturing feasibility and safety by simulating mechanical properties such as radial force, compressibility, and fatigue performance. Our process shortens the development cycle and accelerates your time to market.

02

We ensure the rapid completion of prototype manufacturing with experienced process team, various advanced manufacturing equipment, stable supply chain resources and perfect production management system.

03

Our testing laboratory has a wide range of testing instruments to verify prototype performance which can help you identify design defects or safety issues to optimize the structural design of products and reach performance requirements.

04

Product design

Simulation

Prototyping manufacturing

Product testing

Exceptional product processing and development team

Outstanding laser manufacturing capabilities:

Advanced nitinol processing capabilities:

Industry leading metal processing capabilities:

Simulation and testing laboratory

Reliable supply chain management

Comprehensive production management system

We take pride in our customer service and aim to provide 5-star support.

+86 19005195075

Copyright © 2024 Paisheng Technology (ChangZhou) CO., Ltd. All Rights Reserved.

Sitemap