Stainless steel

Nitinol

Platinum-iridium

Cobalt-chromium

Polymers

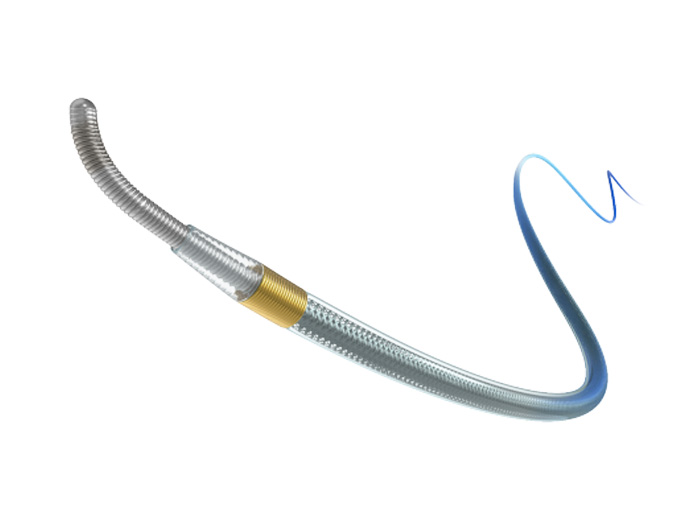

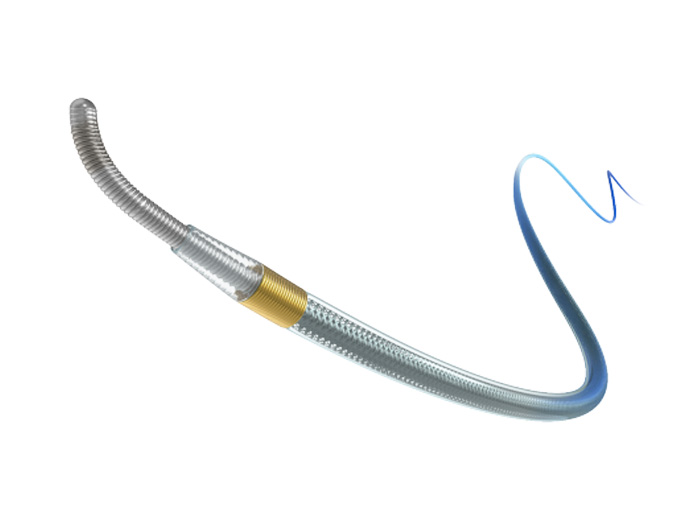

Micro guidewiresMicro catheters

HypotubesDelivery systems

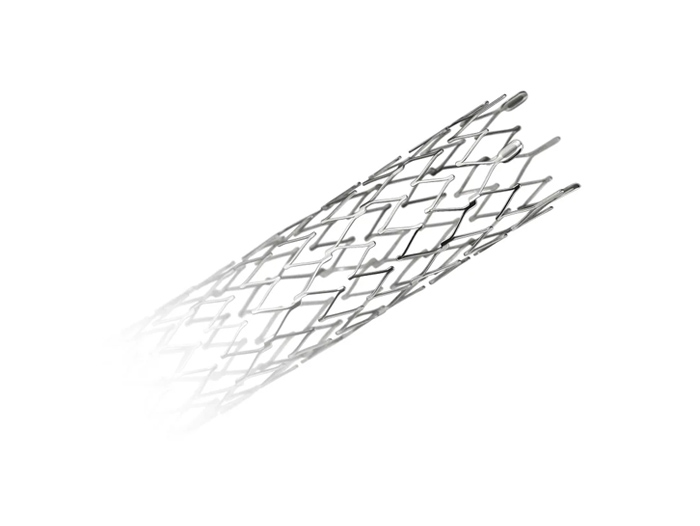

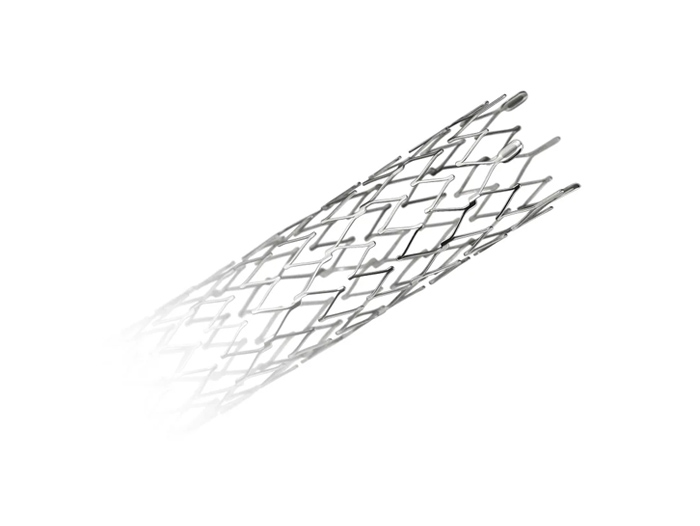

Braided stentsEndoscopes

Other highly specialized components

Material thickness: 0.05mm-0.5mm

Weld spot range: 0.03mm-0.5mm

Welding depth:0.01mm-1mm

Welding methods: butt welding、overlay welding、splicing welding、melting ball welding, etc

Stainless steel

Nitinol

Platinum-iridium

Cobalt-chromium

Polymers

Micro guidewiresMicro catheters

HypotubesDelivery systems

Braided stentsEndoscopes

Other highly specialized components

Material thickness: 0.05mm-0.5mm

Weld spot range: 0.03mm-0.5mm

Welding depth:0.01mm-1mm

Welding methods: butt welding、overlay welding、splicing welding、melting ball welding, etc

We take pride in our customer service and aim to provide 5-star support.

+86 19005195075